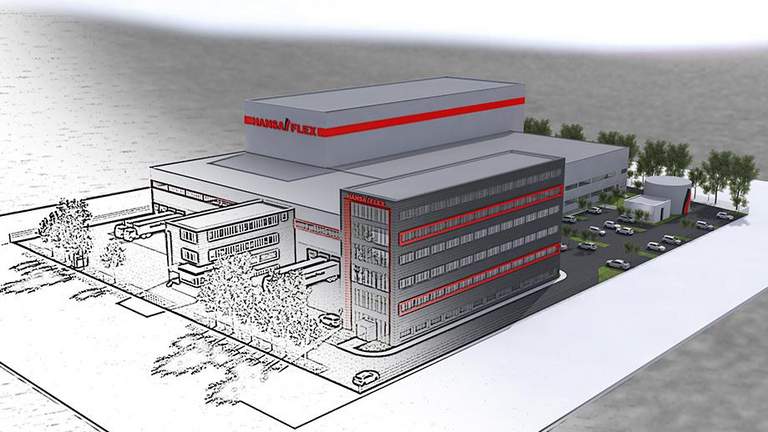

Company HQ will see major expansion: Setting a clear signal for the future

At an investment volume of 18 to 20 million euros, the extensive new building at Von-Thünen Street 14 is by far the largest construction project in the entire history of the company. The new building complex is being constructed just a few minutes’ walk from company HQ at Zum Panrepel 44 on the Bremen-Mahndorf business park. Covering a total area of over four hectares, the two locations will together form the global headquarters of HANSAFLEX AG. The new location at Von-Thünen Street alone, which was acquired in the summer of 2018 together with the buildings on the site, measures around 18,000 m2.

Capacities for further growth

In the next few weeks the first construction vehicles will arrive here and start implementing the ambitious construction project. By the end of 2021 a total of four intelligently interconnected structures will then be created, offering a variety of logistical advantages as well as sufficient space for further growth and effective teamwork. “With this forward-looking new building at our preferred location, we are securing the capacity for further sustainable growth by the HANSA-FLEX Group”, emphasises Uwe Buschmann, who as the member of the Management Board responsible for logistics and materials management is largely in charge of the project. “In addition, with this ambitious and forward-looking investment decision we wish to send a positive signal to our workforce, customers and business partners in these turbulent economic times”.